While there are many potential hazards to check on site, there’s one you can remove by asking the right questions when buying from your builders’ merchant. No-one wants to expose themselves or their staff to falling through a sub-standard piece of plywood, so it’s important to check you have the right product for the build situation.

Research by the Timber Trade Federation (TTF) over the past few years has revealed that plywood products are not always what they seem. We found that neither the species of wood declared for the face or the core, nor the glue bonds – essential to maintaining the product’s integrity - could always be trusted, particularly on plywoods imported from China. We therefore took on the challenge of changing that situation.

Timber Trade Federation members, who include builders merchants and timber distributors who supply them, must now conduct independent third-party testing of product glue bonds on plywoods being brought in from China. They must also conduct independent species testing, to make sure the plywood they are buying or selling is what’s stated on the pack. From January 2018, those factors also became part of our Responsible Purchasing Policy, to which all TTF members adhere, and against which their performance is regularly audited.

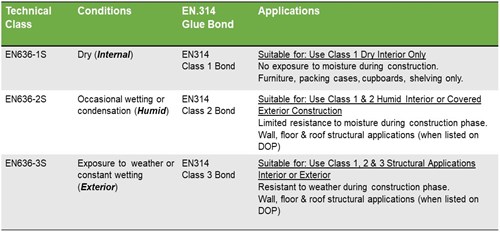

Job done? Only partially so. The key factor is to make you, the builder, aware of what you need to ask for when ordering plywood, including which product has the right glue bond to make it safe for your intended use. Plywood with a Class 1 EN314 Glue Bond under is only suitable for dry interior situations; you may find this labelled as ‘Use Class 1 Dry Interior Only’, or as ‘EN636-1S Dry (Internal)’. It should not be exposed to moisture at any time during a build.

The TTF is recommending that our members only stock or trade in plywood products of the next Class 2 and upwards. Plywoods listed as EN636-2S with an EN314 Class 2 Glue Bond on the product’s Declaration of Performance (DOP), are suitable for Use Class 2 interior situations. That’s where the build conditions are humid, where the plywood comes into contact with condensation, or where products may receive a rare wetting.

EN636-3S plywood with an EN314 Class 3 glue bond for Use Class 3,are suitable for all applications under Use Classes 1-3, including situations where they are exposed to weather during construction. Their DOP will detail each product’s uses e.g. for structural applications. If in doubt, ask your builders’ merchant for advice and ask to see a copy of the product’s Declaration of Performance. Make sure you’ve got what you ordered when it arrives on site by checking the documentation on delivery, and make sure you store that material suitably according to its Use Class.

Sourcing the best products that project budgets can encompass will afford your reputation, and your people, greater defence. Safety comes at a cost, but from what we’ve seen through our research, you could be paying a price of a very different kind by opting for a cheaper, lower Use Class and lower Glue Bond plywood product.