With the UK kitchens market alone being valued at around £4.4 billion pre-pandemic, excluding the bedrooms and bathrooms sectors, the diversity of wood-based surfaces and their design possibilities is worth investigating.

Spare spending capacity

The Office for Budget Responsibility estimates that by summer, households across the nation will have put around £180 billion into savings. A quarter of these savings will be spent in the next five years, with much of that likely in the second half of 2021 and the first half of 2022. We look at a range of products to help you capture a share of homeowners’ spend.

Mix & match: a shift in kitchen design philosophy

Decorative surfaces are hugely varied and can allow you and your customers to express their creativity and individuality. In the past, kitchens featuring a unified decorative style for worktops and cabinetry were favoured. Today, tastes have changed and many more manufactured variations on a theme are available. David Wilson, Kitchen Development Manager at MGM Timber Merchants in Scotland, says: “Mottled concrete-looking and wood-grain effects are some of the most popular types of surface and we are able to design different combinations within a kitchen.

“Walls above kitchen cupboards can feature one surface treatment, cabinetry doors another, while the worktop and kitchen island may feature another toning material. The concrete-look and wood-grain effect often look good together, giving an ‘industrial’, modern feel to a kitchen.

“Solid timber worktops are still desired by some clients though others prefer not to engage with having to sand and oil a solid wood worktop surface up to several times a year. The advantage of modern wood-based and laminate surfaces is that they can be supplied to exact lengths, mitred, and with edging in place.”

Using samples: from textiles to metal

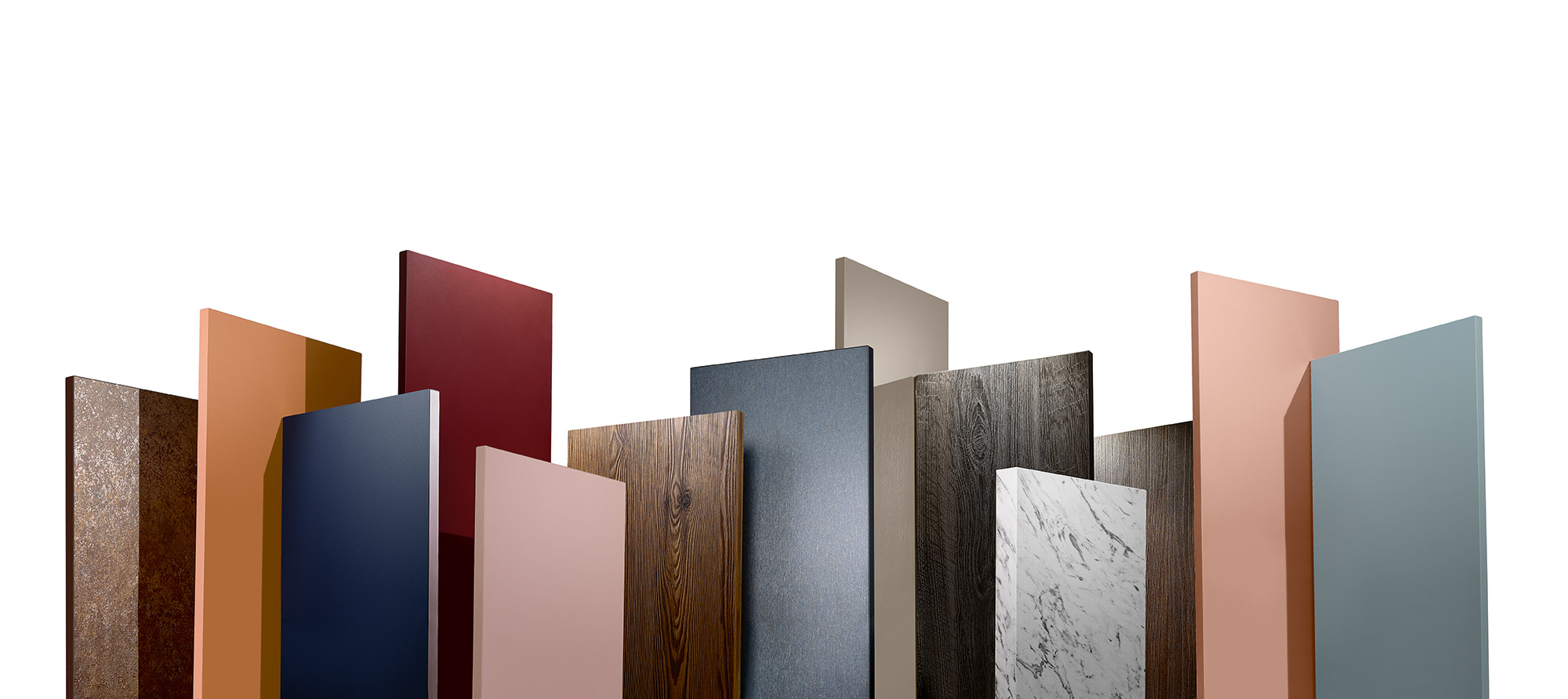

With individuality a feature of high end refurbishments and kitchen projects, having samples to hand helps to bring potential projects to life for homeowners. James Latham Timber, specialists in decorative surfaces, has a sample-ordering service on their website, and a YouTube channel to help you show a variety surfaces to clients.

“Our range of Egger decorative surfaces covers a multiplicity of choice, from the feel of various textile-covered surfaces to a textured metallic feel, a dark charred timber effect, a concrete effect, and highly realistic woodgrain and marble effects. Each can be based on either MFC (melamine-faced chipboard), MFMDF (melamine-faced MDF) or laminates,” says Stuart Devoil, Group Head of Marketing. “Samples allow you to better manage customer expectations and to demonstrate the breadth of your knowledge."

Timber flooring alternatives

It’s not just the work surfaces and cabinetry to be considered when discussing options with homeowners. Flooring is equally important. As with surfaces above, you’re selling the overall ‘look’ rather than necessarily a particular product. In these times of shortages it pays to look around at alternatives.

Dave West, Joint Managing Director at W L West & Sons, says: “We should be using more of our local temperate hardwoods, in addition to the obvious Oak. There are a number of British-grown species out there which can be aesthetically pleasing as flooring. Ash and Beech are two examples; we offer machine flooring in both to order. Beech needs more attention in its drying and machining, but that’s where specialist sawmillers like W L West & Sons come in. We’ll always try to find a solution for a customer,” West adds. Specialist sawmillers may also be able to help with creating matching finishing materials such as doors, skirtings and architraves to order.

Flooring that is engineered for heating

Beyond solid timber floors, engineered wood flooring is the choice of many working on projects featuring under-floor heating. Engineered flooring features a top ‘wear layer’ of solid timber, backed by layers with the grain running in different directions. This evens out potential movement in any one direction, making it more stable and able to withstand a better range of conditions. An expansion gap is still required.

With the fashion for bi-fold doors leading from kitchen to garden, homeowners should opt for a lacquered finish to minimise the potential for water spoiling the flooring. Lacquered finishes also help to resist staining from spills if used in a kitchen situation. If an engineered floor is being fitted over concrete, a product with a 14mm thickness may suffice; if fitting over joists a 20mm thickness may be needed. All engineered wood flooring, like its natural solid counterparts, should be left to acclimatise for a minimum of three days in the room in which it will be used.

Parquet flooring is back

After a long absence, parquet-effect flooring is back in fashion, and available in engineered form to suit modern household needs. As with decorative surfaces for other areas, the choice of colourways and natural grain patterns in the top wear layer of the flooring is extensive. Manufacturers like Timber Trade Federation (TTF) member Atkinson & Kirby have 20 different variations in their Oak parquet engineered flooring range alone and have samples available to help your homeowner make the right choice.

This article was originally published in the August / September 2021 edition of the Master Builder magazine. Members can login to view a copy.